Novvi Dielectric Cooling Fluid – 281

A 100% biobased and precision engineered solution for immersion cooling, DCF-281 eliminates the tradeoff between performance and sustainability.

As data centers work to meet the strenuous cooling demands brought on by the Age of Artificial Intelligence, Novvi has created a cost-effective renewable fluid to meet those demands.

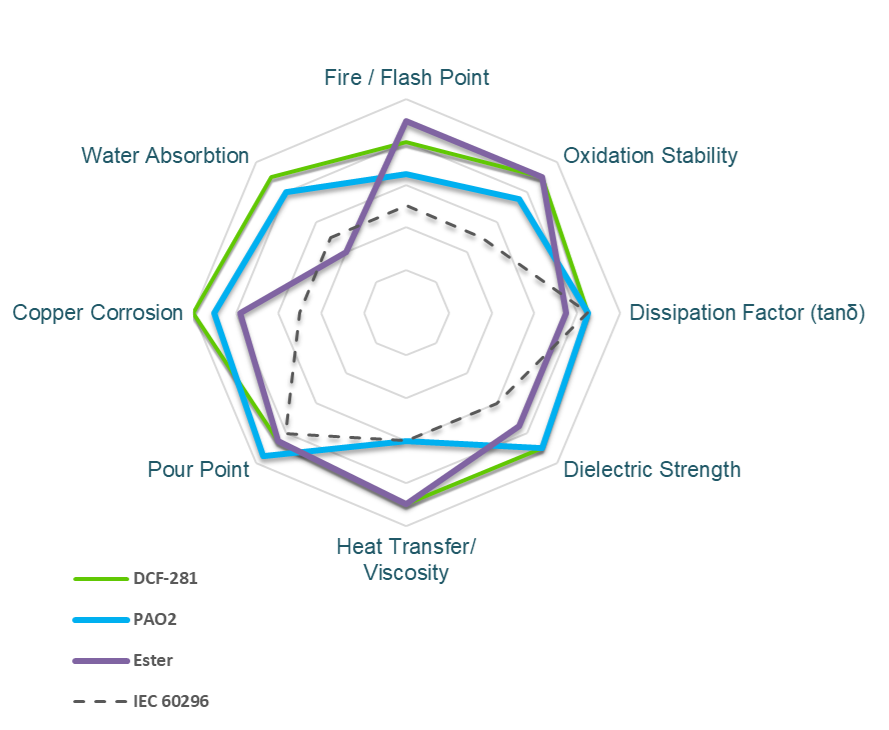

Leveraging our unique manufacturing process, Novvi’s DCF-281 is precisely formulated to match or exceed the thermal, chemical, and electric properties of commercial PAO and GTL-based fluid.

- Thermal Performance

- Higher thermal conductivity and heat capacity than similar synthetic fluids, PAO, GTL, or Group III base oils

- Chemical Stability

- Highest oxidation stability and long-term aging performance. Extreme temperature, UV, and chemical resistance

- Dielectric Properties

- Lowest dielectric constant and dissipation factor. Non-polar fluid with lowest water adsorption.

- Health and Safety

- High Flash Point and Low Vapor Pressure eliminate fire, odor, and health concerns.

Typical Properties – DCF-281

| Properties | Method | Typical Values |

| Viscosity, 40°C (cSt) | ASTM D7042 | 10.50 |

| Viscosity, 100° (cSt) | ASTM D7042 | 2.81 |

| Flash point (°C) | ASTM D92 | 192 |

| Autoignition Point (°C) | ASTM E659 | 325 |

| Biobased Carbon Content | ASTM D6866 | 100% |

| Thermal Conductivity 40°C (W/m∙K) | ASTM D7896 | 0.1406 |

| Specific Heat Capacity at 40°C (J/g∙K) | ASTM D7896 | 2.11 |

| Dielectric Constant | ASTM D924 | <2.1 |

Product Date Sheets

- Novvi DCF 281 Immersion Cooling TDS Novvi-DCF-281-Immersion-Cooling-TDS.pdf