October 3, 2022

Thermal management fluids for electric vehicles are the new golden prize for some suppliers of lubricant base fluid. Trevor Gauntlett considers some of the entries in the race.

It is a received wisdom that the arrival of electric vehicles will result in a significant downturn in lubricant volumes. Since fully electric vehicles will have no crankcase, passenger car lubricant volumes will start declining soon, as the amount of fluid required to cool and lubricate an electric motor is much smaller than that for an equivalent vehicle powered by an internal combustion engine. There are also concerns that replacing a 10-speed automatic transmission in an ICE vehicle, for example, with a single reduction gear or a 2-speed transmission in an EV will further reduce volumes in each vehicle.

At the end of 2021—around the time of COP26 in Glasgow—governments vied with each other to have the earliest ban on ICEs. The volume outlook for lubricant blenders was gloomy, with companies like Bloomberg New Energy Finance forecasting that 15% of passenger vehicle sales could be zero-emission vehicles by 2025 and 60% of all light-duty vehicles could be zero emission by 2040.

Optimism from Some

Not everyone has a gloomy view of the market, however. Before COP26, several companies were promoting their products for rapid cooling of EVs.

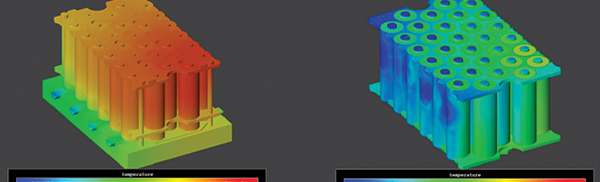

Bethan Warren of Cargill presented an early COVID-era webinar entitled “Potential Uses for Dielectric Fluids in Hybrid and Electric Vehicles.” In the webinar, she presented computational fluid dynamics, or CFD, modelling that simulated a battery pack under ultra-fast charge conditions, with a heat output per cell of 9 watts, created in partnership with D2H Advanced Technologies. If the battery cells are immersion cooled, temperatures are on average 2.8 degrees Celsius cooler than a cold plate cooled set up. Immersion cooling involves the coolant directly contacting the battery cells, rather than cooling a heat sink thermally bonded to the battery cells.

Also during 2020, Volker Null, technology manager thermal & dielectric fluids at Shell, gave conference presentations highlighting the benefits of Shell’s gas-to-liquid base fluids as thermal management fluids for immersion cooling. These “can help increase power and energy density ratios and significantly enhance cell durability,” he told Lubes’n’Greases.

Fast forward to June 2022 when there was another flurry of activity. Bill Downey of Novvi and Null spoke on consecutive days at two different conferences. Later that month, Chevron Phillips Chemical Co. announced a doubling of capacity at its Beringen plant in Belgium, stating in a press release that the growing demand for polyalphaolefins is partly a result of “new applications such as electric and fuel-efficient vehicles and heat transfer fluid.”

Which Applications?

Rapid charging addresses two of consumers’ principal concerns regarding EV adoption. The direct benefit is the reduction in charging time when the driver is out and about, while an indirect benefit is reduction in range anxiety, as each charging station is occupied for less time. This is particularly important in places where the distance between chargers is more than a few miles. For OEMs, extending battery life reduces the environmental impact of the battery and the vehicle, enhancing sustainability credentials.

Of course, it’s not just heat that must be dissipated; there are also parts to lubricate. But which parts? With technology evolving rapidly, there is no dominant mechanical engineering solution that dictates likely fluid use. Therefore, it is possible that some OEMs will require a single fluid to cool the power electronics and batteries, while others may require one fluid to also lubricate the motor and/or transmission.

“Novvi has seen that the most advanced light-duty OEMs are looking for one fluid to cool and to lubricate,” Downey said. “In heavy-duty, there may still be a separate fluid for battery cooling.”

Others are anticipating separate e-motor and thermal management fluids. “We believe that cold-plate versus immersion cooling choice may be based on class of car,” Warren said. “Faster, more expensive cars may be cooled via immersion because it can offer the very fastest charging speeds, whilst smaller, lower performing, cheaper cars may continue with a cold-plate solution.”

Even if the niche is only the most expensive 10% of passenger cars, that accounts for 8-20 liters of fluid in 60-100 million vehicles by 2040.

Features, Advantages and Benefits

The requirement to lubricate could rule out some novel fluids and steer the debate about features, advantages and benefits toward familiar ground for Lubes’n’Greases readers.

Ken Hope, global PAO technical services manager for Chevron Phillips Chemical, told Lubes’n’Greases that “the most important parameters for thermal management fluids are viscosity, density, specific heat and thermal conductivity … The modelling of fluid flow is frequently dominated by viscosity.” It is essential “that the volatility, flash and fire points have met the necessary safety requirements.”

Downey added: “The fluid must be compatible with the electronic components as well. Ultimately, the thermal conductivity and heat capacity of the fluid is key; together they constitute the thermal properties. It is important to know that the bulk properties of the fluid are key; it is hard to make fundamental changes with additives.”

Null stated that a thermal management fluid must have “good dielectric (minimize arcing and short circuits) and thermodynamic properties, low viscosity, long term stability, good material compatibility and be noncorrosive.”

Density is an interesting parameter in these discussions, too. The heat transfer coefficient of a fluid is improved if the fluid density, thermal conductivity and specific heat capacity are high and the viscosity is low. However, high density means more weight for the same volume, so some fluid suppliers are promoting the weight benefits of their less dense materials against the competition.

All the necessary thermal parameters can be found in API Group III and Group IV base stocks and can be tailored into esters. The potential of the rapid charging market for EVs has focused the minds of the principal players on differentiating their products within the general sweep of the API groups. Null asserts that GTL thermal fluids have “excellent” dielectric properties, thermodynamic properties and material compatibility.

Cooling Down to Speed Up Charging

Filling up a conventional gasoline- or diesel-powered car takes around five minutes, but the fastest charging electric cars commercially available today can be recharged in around 20 minutes from 10% battery charge to 80%. When polled by a German OEM, most consumers stated that 10 minutes was an acceptable time to wait for that kind of battery charge and that this time would influence their next vehicle purchasing decision.

“Halving the [charging] time … requires you to double either current or voltage,” Null said. But the heat generated during charging is proportional to the square of the current, so “doubling the current will generate four times more heat.”

However, “battery cells are very sensitive to temperature changes,” Null continued. Batteries have a small operating window for efficient operation between around 15°C and 35°C. High temperatures reduce battery life, so cooling is vital. Ultra-fast charging can result in around 20 kW of excess heating power in the battery during charging. This is enough energy to heat a central European house for a day during the winter. On the other hand, cold batteries discharge slowly and do not charge well, so it is advantageous to warm the battery before starting or charging an EV on a cold day.

Sustainability

Downey’s presentation about Novvi’s Sustainable Synthetic Base Oils in June referenced their potential use as thermal management fluids. “We tested a range of fluids on a closed-loop OEM rig, which had a pump, air-cooled heat exchanger and a series of tubes to simulate a battery. We controlled the inlet temperature and the flow rate, and measured the difference in various types of base oils.” Novvi’s products showed better performance than equiviscous (at 100°C) API Group III base oils (including GTL base oil) and comparable performance to PAO.

Novvi can also add bio-sourcing. “Novvi’s fluids are unique,” Downey said. “They are the only hydrocarbons in the space that are based on plant oils. In addition, they are carbon negative. This gives the formulator great performance and options for differentiations.”

Not Just EVs

Warren pointed out that ultra-fast chargers themselves can also benefit from liquid cooling. At the highest currents, cables must be very thick to prevent significant heat build-up within the cable. These are less flexible and more expensive to produce. A liquid cooled cable system allows for a smaller cross-section of copper to be used for a given charging power, resulting in a cable that is easier

to handle and connect to the car.

In the same market, Shell’s collaboration with Austrian battery development company Kreisel Electric includes battery-buffered, high-performance charging platforms.

Others have seen the attractions of data center cooling, which could offer a larger market for similar fluids. “As our dependence on data and the speed at which we consume it continues to grow, so will the multi-billion-dollar business of data centers,” said Matthew Joyce, vice president corporate ventures at Lubrizol. “This expected growth will be accompanied by increasing thermal demands, energy usage and water consumption, and the need to utilize space inside the data center as efficiently as possible. These challenges are presented not only to data center owners and operators, but the technology industry as a whole, who have made sustainability a centerpiece of their business agenda.” Lubrizol is also offering thermal management fluids for EVs.

Subtle Modifications

Many thermal management fluids are new and subtly different from those already on the market. Eduardo de Azevedo, business development manager, new OEMs at Shell, told Lubes’n’Greases: “The fluids Shell is offering for data center thermal management are formulated considering all the specific requirements for this application, therefore slightly different from those offered for EVs and those grades used as lubricants base fluids.”

Novvi has developed a dedicated thermal management product as well. “With our SynNova 4 showing a cooling performance a bit better than PAO, we set out to make the performance significantly better,” Downey said. “The result is our Novvi 4LT, which has all the lubrication properties of SynNova but better thermal and traction properties.”

Cooling an Electric Future

The transition to electric vehicles is gaining pace, despite the slow-downs due to chip shortages, COVID-related supply chain disruptions and the potential global economic recession. While the development of fluids for e-axles, electric motors or transmissions has probably caught most attention from lubricants professionals, thermal management of the batteries, control electronics and inverters—plus the onshore rapid charging stations—are markets full of potential for those engaged in the supply of lubricant base fluids. It’s open to speculation whether esters, PAOs or products closely related to API Group III base stocks will win out, or whether they will each find a niche.